viernes, 9 de diciembre de 2016

Refrigerant Charge

Refrigerant Charge

Refrigerant R-12 is used in most transport systems at the present time, but R-502 is well suited fot low temperature applications, and its use is increasing. Since R-502 creates a greater power requirement for a given compressor displacement than R-12, the motor-compressor must be properly selected for the refrigerant to be used. Different expansion valves are required for each refrigerant, so the refrigerants are not interchangeable in a given system and should never be mixed. receivers for R-502 require higher maximum working pressure than those used with R-12, so normally it is not feasible to attempt to convert an existing R-12 unit fot the use of R-502.

The refrigerant charge should be held to the minimum required for satisfactory operation. An abnormally high refrigerant charge will create potential problems of liquid refrigerant migration, oil slugging, and loss of compressor lubrication due to bearing washout or excessive refrigerant foaming in the crankcase.

System should be charged with the minimum amount of refrigerant necessary to insure a liquid seal ahead of the expansion valve at normal operating temperatures. For an accurate indication of refrigerant charge, a sight glass is recommended at the expansion valve inlet, and a combination sight glass and moisture indicator is essential for easy field maintenance chexking. It should be born in mind that bubbles in the refrigerant sight glass can be caused by pressure drop or restrictions in the liquid line, as well as inadequate liquid subcooling. Manufacturer's published nominal working charge data should be used only as a genral guide, since each installation will vary in its charge requirements.

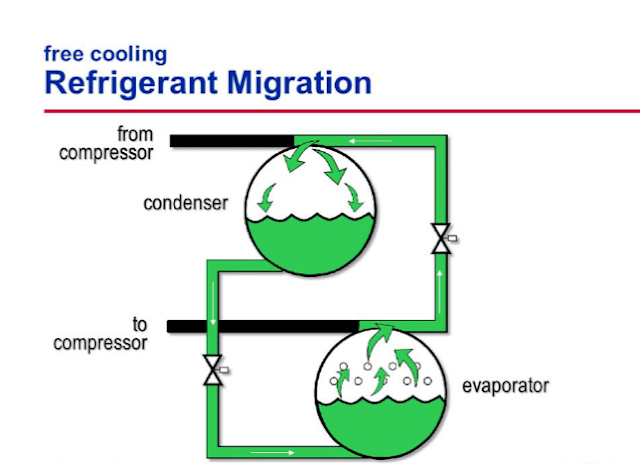

Refrigerant Migration

Refrigerant migration is a constant problem on transport units because of the varying temperatures to which the different parts of the system are exposed. On eutectic plate aplications, liquid refrigerant will be driven from the considensing unit to the plates during the day's operation, with the threat of floodback on start-up. On both plate and blower units not in operation, the body and evaporator inmmediately after operation will be colder than the condensing unit, causing migration to the evaporator . During daytime hours the body and evaporator will warm up, and because of body instasulation will remain much warmer than the compressor during the night hours when the ambient temperature falls, resilting in a pressure differential sufficient to drive the refrigerant to the compressor crankcase.

Excessive refrigerant in the compressor crankcase on star-up can cause slugging bearing washout, and loss of oil from the crankcase due to foaming. Dilution of oil with excessive refrigerant result in a drastic reduction of the lubricating ability of the oil. Adequate protective measures must be taken to keep migration difficulties at a minimum. Consideration shoul be given to keeping the refrigerant charge as low as possible, using a pump down cycle, use of a suction accumulator, and the use of a liquid line solenoid valve.

Suscribirse a:

Enviar comentarios (Atom)

China refrigerant gas

ResponderEliminar